Hemingray Lights the World

by Bob Stahr

Reprinted from "Crown Jewels of the Wire", May 1997, page 7

The Hemingray Glass Company was known the world over for quality, dependable

insulators. However, Hemingray made much more than just insulators. A list of

products from Williams' Cincinnati Directory and Business Advertiser of 1867

includes the following: "Fruit jars, lamps, lanterns, chimneys, brandies,

hock wines, demijohns, screw cap flasks, tumblers, and a great variety of table

ware. Also, philosophical apparatus, and round & oval shades for artificial

flowers and statuettes. Solar, sun, and comet burners on hand in large

quantities." This list was a curiosity to me. If Hemingray made so much,

why can't I find it?

The search began with reading several Old Bottle Magazine

articles on Hemingray. Two names popped up a few times, Glenn Drummond and John

Webster. Glenn and John both collected Hemingray items in the mid to late 1970's. Their proximity to Covington sparked their interest in the early glass made

there. It was from Glenn that I heard my first rumor that the factory site of

Hemingray in Covington, KY was dug. Glenn had thought that some archaeologists

dug the factory and that the shards were taken to a museum or college. Glenn

suggested that I look up John. I did, and gave him a call. John confirmed that

the site was dug, and stated that "the shards were taken to the museum in

Devou Park" (in Covington).

With that information, I called Roger

Lucas, with whom I had been in contact ever since Roger and Darrin Cochran

displayed Hemingray dump items at the London, OH show. Roger and I had made a

previous trip to Covington to look at the Hemingrays' cemetery plot and to look

around the town for Hemingray items in antique shops. After telling Roger about

the dig and the museum, we decided it was worth the effort to make another trip

there. This time we looked up the cemetery plot of the Grays' and drove up into

Devou Park. After driving around we located a large mansion within the park. In front of the mansion was a locked gate at the entrance to a parking lot. The

sign at the gate read "Behringer-Crawford Museum." I wrote down the

name and we left to go about the rest of our business.

Back home and later in

the week, I called information for the phone number of the museum. I called and

talked to the receptionist who confirmed that they did own some Hemingray glass.

She referred me to one of the archaeologists who was involved with the dig.

After talking with the archeologist, I learned that the Hemingray factory site

was dug because Covington was redeveloping the riverfront where the factory once

stood. Federal money was involved in the re-development which meant an

archeological survey had to be done. The preliminary survey consisted of digging

a small hole with a backhoe. To our luck, one of the first things found in the

test hole was a complete bottle mold! With the items that were found in the test

hole, it was determined that the entire factory should be excavated. The entire

factory was excavated in 1986 and all the shards that were determined to be

important were catalogued, boxed up, and given to the museum. A three volume

report was written and a display was set up for a short time.

The archaeologist

was quite receptive to my questions. I asked how many shards of glass they had

and the archeologist responded with "approximately 200,000." This was

very exciting to hear and resulted in my asking to view some of the items. An

appointment was set up, and Roger Lucas joined me in my trip there again. Prior

to leaving, I told Rick Soller about it as well. Rick was going to Ohio that

week and would drop down to join us that day.

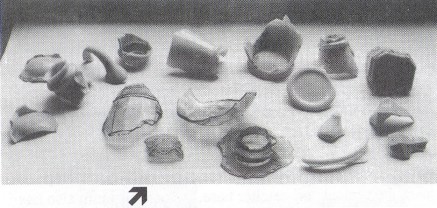

The archaeologist pulled about six

boxes from the display material for us to look at. There was a wide variety of

items including bottles, fruit jars, insulators, tableware and kerosene lamp

parts. I already had an idea of what bottles and fruit jars they made, but the

tableware and lamp parts were a total surprise. After we all took several

pictures of the shards, we left for home.

It was no secret to me that Hemingray

made lamps. I have numerous advertisements and references to lamp manufacture

covering four decades and I know Hemingray had rights to at least four patents

relating to lamp manufacture. The patents are:

March 30, 1869

D 3,436

Design for

a lamp chimney

February 23, 1875 160,016

Paper perforating machine (for paper lamp shades,

etc.)

May 14, 1878

D 10,678

Design for a glass lamp shade shaped like a human head

March 4, 1879

212,850

Machine for flaring and crimping lamp chimneys

Hemingray also held patent rights to their famous Elgin Oil can which held

the kerosene for filling these lamps. Proving that Hemingray made lamps was

easy, all I needed was proof of what patterns they made.

Upon arriving home from

the trip to the museum, one of the first things I did was go to the library.

Once there I found two excellent books by Catherine Thuro. The books, Oil

Lamps--The Kerosene Era in North America and Oil Lamps II, gave nomenclature,

history and plenty of pictures that helped me identify the pieces of the lamps

that were dug at Covington.

At this point it is necessary to identify styles and

different parts of lamps. The fount is the bowl-shaped reservoir the oil was

kept in, the burner is the metal portion that holds the wick, and the chimney is

the shade that sits on the burner to protect the flame. Stand lamps have the

fount on a pedestal-type base, finger lamps have small handles so they can be

held onto with a finger and carried across a room, and side lamps consist of a

tin wall hanger with a glass fount that sits inside of it.

A thumbprint design

in the fount of a lamp means that the fount has a pattern of "spots"

of thicker glass in a systematic pattern. Because of the thicker glass, these

spots appear in a darker color, thus the name thumbprint was given.

Hemingray

stand lamps were made in a three step process. The stand or base portion of a

lamp is pressed in a mold, the fount is blown in another mold, and the two are

brought together while still hot and "welded" together. This

construction makes it possible to mix and match different founts and different

bases. This can easily be seen in several of the stand lamps shown in this

article.

One unique feature of Hemingray made lamps is the way that the bases on

many of them are molded. Of the 11 lamps that I own, only one finger lamp and

one stand lamp lack what I call a "drip catcher base." When filling

the oil lamps, oil usually spills on the fount and migrates down the side of the

lamp to the base. The "drip catcher base" keeps these drops of oil

from staining tablecloths. The "drip catcher base" is not unique to

Hemingray, but the way it is made appears to be. Founts can also be made with

drip catchers, and these are rather specifically made as well.

As you probably noticed, on the front cover are pictures of the Stanbury and

the Vera lamps next to insulators of matching colors. I believe this helps

explain the variety of colors in insulators that we see from this time period.

Based on the styles and molding techniques of the lamps, they would have been

made in the 1880's to the turn of the century. Because of the lack of drip

points on the insulators of matching color, we know the insulators were made

prior to 1893 and most likely in the late 1880's since Hemingray's Muncie,

Indiana plant became operational around 1889 and the Covington plant supposedly

closed around 1892. It is quite possible that these insulators may have been

made out of a batch of excess glass that was used in lamp production.

Medium Image (68 Kb)

Large Image (222 Kb)

The following pictures are of shards dug at the Covington factory and lamps from my

collection. In addition to shards dug at Covington, shards were also dug at the

Muncie, Indiana factory by Roger Lucas and Darrin Cochran. For photographing

purposes, some of the burners and chimneys have been removed.

Lamps I suspect

were made by Hemingray but are unconfirmed are Sheffield Swirl, Artichoke and

Shane patterns. Lamps confirmed to be made by Hemingray and the location they

were found follow. (Please refer to books by Thuro for lamps not pictured in

this article.)

|

Daisy & Button finger lamp

|

Covington, KY

|

|

Vera

|

Covington, KY

|

|

Stanbury

|

Covington, KY

|

|

Cooper

|

Covington, KY

|

|

Inverted Thumbprint and Prism Stem

|

Covington, KY/ Muncie, IN

|

|

Pearl Loop

|

Muncie, IN

|

|

Corner Windows

|

Muncie, IN

|

|

Simple Solid

Stem *

|

Muncie, IN

|

|

Simple Hollow Stem*

|

Muncie, IN

|

|

* Lamps not pictured in Thuro.

Names were given to eliminate confusion.

|

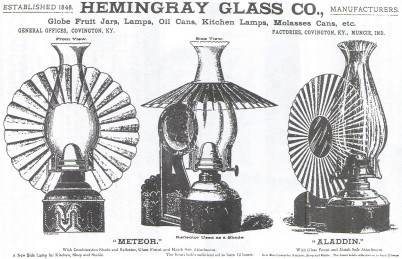

Shown on the following page is a beautiful Hemingray advertisement from the

trade journal China, Glass, and Lamps from December 2, 1891. The patent (Aug 12,

1879) on the Meteor lamp was not assigned to Hemingray although I suspect they

obtained rights to the manufacture of it. Courtesy of Dick Roller.

Medium Image (128 Kb)

Large Image (332 Kb)

|

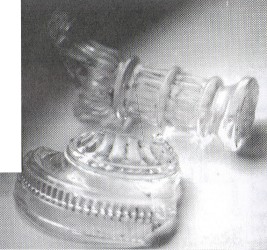

A clear glass Cooper Lamp and clear glass shards of a Cooper Lamp dug at the

Covington, Kentucky factory of the Hemingray Glass Company.

|

|

A portion of the advertisement of the Chicago wholesaler French, Potter,

and

Wilson from the February 1888, Vol. 7 No.2 issue of American Potter

and

Illuminator showing the Cooper lamp. Courtesy of Catherine Thuro.

|

Two amber and one clear applied handle shards dug at the Covington, Kentucky

factory of Hemingray Glass Company. |

Clear glass Daisy and Button pattern finger lamp.

Note the applied handle.

Peacock blue glass shard of Daisy and Button pattern finger lamp dug

at the

Covington, Kentucky factory of the Hemingray Glass Company surrounded

by

a shard of an amber Globe Tobacco jar and several syrup pitcher shards

in

various colors of milkglass.

|

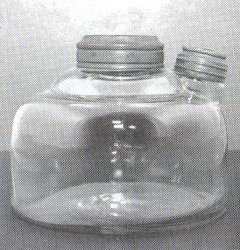

Clear glass side lamp with oil filler. Note the similarity to the side lamps

advertised by Hemingray. This lamp also exists without the oil filter. |

|

On following page:

(Top Left) Clear glass lamp with Cooper fount and Teardrop base. *

(Top Right) A Simple Solid Stem clear glass lamp with the typical "oil

catcher base." *

(Lower Left) A Simple Solid Stem clear glass lamp with the typical "oil

catcher base." Note this lamp also has a "drip catcher fount"

like Inverted Thumbprint and Prism Stem lamp (see page 13). Courtesy of Roger

Lucas. *

(Lower Right) A Simple Hollow Stem clear glass lamp with the typical

"oil catcher base." Note this lamp also has a "drip catcher

fount."

* Lamps not pictured in books by Thuro. Names were given to eliminate

confusion.

|

|

|

Peacock blue glass "Vera" lamp. This lamp also exists in amber

glass. |

Amber glass Stanbury Lamp and a light green glass shard of Stanbury Lamp

(pictured below) dug at the Covington, Kentucky factory of the Hemingray Glass

Company. |

|

|

|

|

Amber Stanbury lamp complete with burner and chimney. |

|

|

|

|

A variation of the Inverted Thumbprint and Prism Stem lamp in

clearglass.

This lamp lacks the Thumbprint pattern in the fount. |

Clear glass lamp with Prism stem and Prism fount and the typical "oil

catcher base." * |

|

|

|

Peacock blue shards of the Inverted Thumbprint and Prism Stem lamp dug at the

Covington, Kentucky factory of the Hemingray Glass Company. |

|

* Lamp not pictured in books by Thuro. Names given to eliminate confusion. |

|